What is overspeeding and why does it damage turbos?

Overspeeding is a term used when a turbo is operating well above its normal operating limits, and the resultant strain of overspeeding can cause untimely failure of the turbo, as well as the internal combustion engine (ICE) and associated components, Tom Wright, our product manager warns.

One of the main causes of overspeeding is insufficient airflow from the turbocharger to the engine, which could be caused by a torn air pipe, a blocked air intake or a leak between the compressor and the engine. If there are any leaks, cracks or poor seals between the compressor and the engine, the turbo will have to work much harder than it should to deliver the required air levels to the engine.

“When the engine needs more air than the turbocharger can supply, overspeeding occurs. The turbocharger then has to work outside of its usual operating limits which can, in extreme cases, cause blade damage including partial loss of blades, fatigue fractures or a burst compressor wheel,” says Wright.

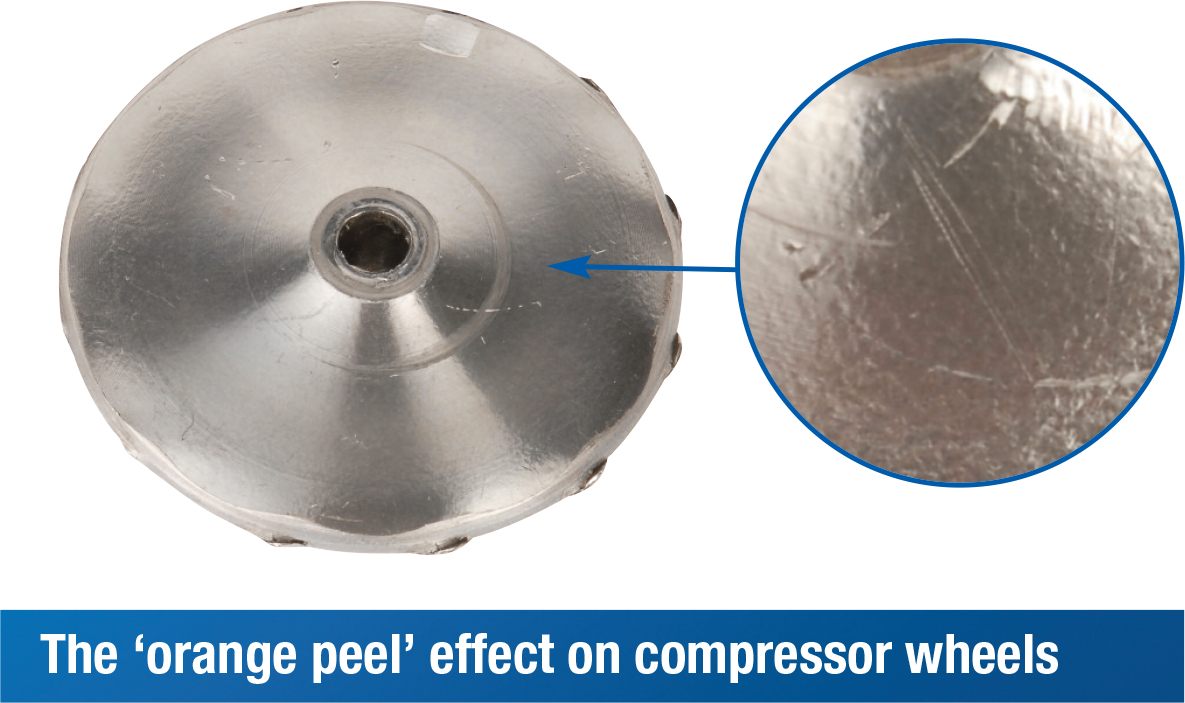

A common symptom of overspeeding is the presence of the ‘orange peel’ effect on the back face of the compressor wheel. This is created by expansion and contraction.

When the compressor wheel is subjected to overspeeding, it grows in size and this expansion causes cracks between the grain boundaries of the material.

In mild cases, the component will return to its original state like elastic but in most cases these cracks begin to grow and eventually, part of the hub can break away.

Another cause of turbo overspeeding can be remapping the electronic control unit (ECU). As drivers of some performance vehicles look to maximise the fuel efficiency or performance of their cars, some turn to remapping or ‘chipped’ engine work, which involves altering the car’s ECU to deliver a different power map or torque range. This can then take the standard factory fitted turbocharger outside the operating range it was design to work within.

Wright advises when diagnosing a turbocharger fault, technicians should be wary that as a consequence of overspeeding the signs of other failure modes such as insufficient lubrication can be present. This is due to the barrier created by the oil film within the bearing systems failing. In turn, this causes contact between components as overspeeding occurs and the turbo fails.

For more information on overspeeding and the preventative measures you can take, visit our dedicated technical article: Common turbo failure – Overspeeding. You can also check out our series of educational technical videos which help identify common failures in warranty situations and provide advice on how to prevent future failures occurring,